Top 10 Benefits of Using Plastic Injection Molds for Manufacturing?

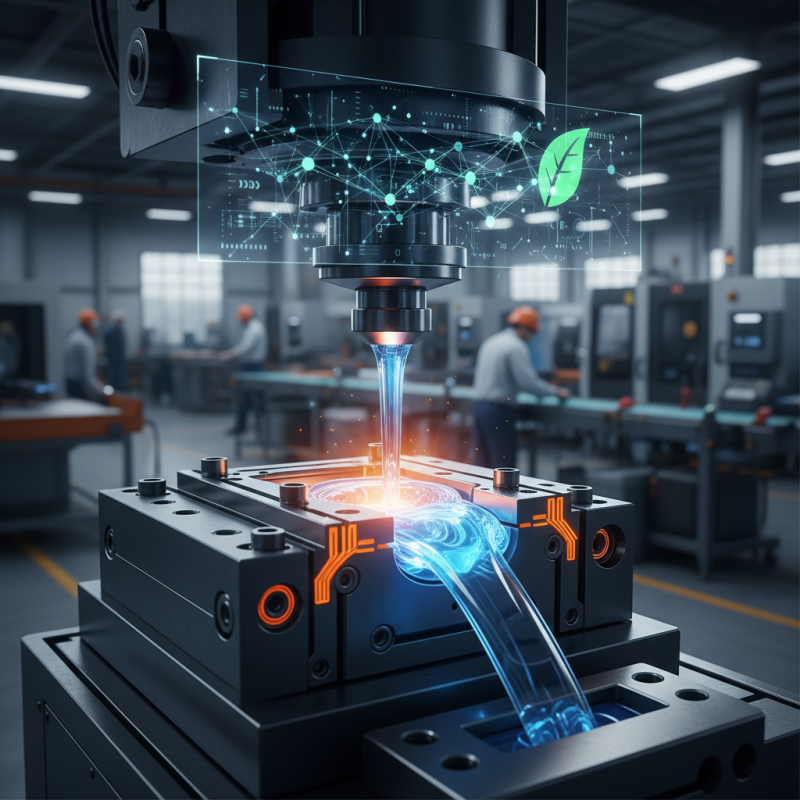

Plastic Injection Molding has transformed the manufacturing sector. This technique offers unparalleled efficiency and precision. According to a report by MarketsandMarkets, the global market for plastic injection molds is projected to reach $30.57 billion by 2026. This growth reflects the increasing demand for high-quality plastic products across industries.

Expert in the field, Dr. Susan Hartman, states, “Plastic Injection Molds are crucial for producing consistent and scalable manufacturing solutions.” These molds allow for reduced waste, faster production times, and lower overall costs. However, the initial investment can be substantial, which may deter some manufacturers.

Moreover, while many focus on the immediate benefits, one must also ponder the environmental impact of plastic manufacturing. Balancing efficiency with sustainability is essential. Thus, understanding the benefits and challenges of plastic injection molding becomes paramount for manufacturers today.

Advantages of Plastic Injection Molds in Modern Manufacturing Processes

Plastic injection molding is revolutionizing modern manufacturing. This process allows for the rapid production of complex parts. It is cost-effective and efficient. Manufacturers can create high-quality products with precision. The speed of production is unmatched in many contexts.

One benefit is reduced waste. The injection process uses materials efficiently. However, improper setups can lead to excess scrap. Regular testing can mitigate this issue.

Another advantage is design flexibility. Molds can accommodate various shapes and sizes. It is essential to consider the mold design carefully. Poor design may lead to weak points in the final product.

Tips for successful plastic injection molding include thorough analysis of materials. Choosing the right plastic is crucial. Monitor the temperature closely to avoid defects. Quality control at every stage is vital for optimal results. Small adjustments in the process can have significant impacts on the final product.

Cost-Effectiveness: Reducing Expenses in Large-Scale Production

Plastic injection molding is known for its cost-effectiveness, especially in large-scale production. According to a report by IndustryWeek, companies can save up to 30% on manufacturing costs when utilizing injection molding. This technique allows for a high production rate, which means more parts can be made within a shorter time frame.

Additionally, the initial setup costs for injection molds can be substantial. However, this expense is quickly offset by the savings achieved through mass production. The ability to produce thousands of identical parts with minimal labor is a game-changer. This efficiency often allows manufacturers to pass savings on to customers, increasing competitiveness in the market.

Despite the advantages, there can be challenges. For example, the cost of creating a mold can be a significant investment. Companies must weigh this against their production volume and timelines. If not managed well, costs may spiral. It’s important to ensure the design is optimized before manufacturing begins. Overlooking details can lead to wasted materials and time, impacting projected savings. Each production cycle should be critically reviewed for potential improvements.

Enhanced Design Flexibility for Complex Geometries and Specifications

Plastic injection molding allows for incredible design flexibility. This is especially crucial when creating complex geometries. Manufacturers can craft intricate shapes that would be challenging with traditional methods. The precision of injection molds accommodates tight tolerances and detailed features. Designers can explore innovative ideas without significant risk.

In addition to adaptability, this process supports quick adjustments. If a design flaw is detected, changes can be implemented efficiently. However, these modifications may require re-evaluation of the initial designs. Miscommunications during design phases can lead to wasted materials and time. It's essential to maintain open dialogue between teams.

Moreover, the initial cost of designing molds can be high. Yet, the ability to produce high volumes can balance this investment. Each mold can make thousands of parts, which makes it worthwhile. Still, some manufacturers face challenges with mold maintenance. Regular checks and repairs are vital to ensure quality output in the long run. Balancing cost and quality remains a constant challenge in the manufacturing world.

Increased Production Speed and Efficiency Compared to Traditional Methods

Plastic injection molding is revolutionizing manufacturing. Increased production speed is one of its significant advantages. Traditional methods often struggle with efficiency. Injection molding processes can produce large quantities quickly. This rapid pace saves time and resources. Manufacturers can reduce labor costs. More output means higher profitability.

Efficiency goes beyond speed. Injection molds allow for precise designs. This precision minimizes waste material. Traditional manufacturing often results in excess scraps. With injection molding, parts come out almost ready for use. This eliminates extra steps in post-production.

Tip: Ensure proper mold maintenance. Regular checks can prevent costly down time. Also, consider your material choice carefully. Different plastics have unique properties. Choosing the right one can enhance efficiency even further. Don’t overlook training for staff. Well-informed workers make better use of advanced technology. Small mistakes can lead to significant delays.

Top 10 Benefits of Using Plastic Injection Molds for Manufacturing

| Benefit | Description | Impact |

|---|---|---|

| Increased Production Speed | Injection molding allows for rapid production cycles, significantly reducing manufacturing time. | Higher output with less downtime. |

| Cost Efficiency | Lower cost per unit due to efficient use of materials and high production volume. | Reduced overall manufacturing costs. |

| Complex Geometries | Ability to create intricate designs that would be difficult with other manufacturing processes. | Enhanced design possibilities and functionalities. |

| High Tolerance Levels | Injection molds can produce parts with tight tolerances consistently. | Improved product quality and reduced waste. |

| Versatility in Materials | Compatible with a wide range of plastics, including specialty materials. | Broader applications across different industries. |

| Reduced Labor Costs | Automation of the injection process minimizes the need for manual labor. | Lower labor expenses and a more efficient workforce. |

| Sustainability | Ability to use recyclable materials and reduce scrap during manufacturing. | Supports environmentally friendly practices. |

| Minimized Waste | Precise material usage leads to less scrap and waste produced. | Improved profitability through efficient resource use. |

| Enhanced Safety | Automation and controlled environments reduce the risk of accidents. | Safer working conditions for employees. |

| Streamlined Production Process | Integration of multiple processes into one continuous flow. | Increased overall efficiency and throughput. |

Consistent Quality and Precision in Mass Production Applications

Plastic injection molding is a game-changer in manufacturing. This method provides consistent quality across mass production applications. It uses high-pressure to inject molten plastic into a mold. The result is uniform products that meet precise specifications. This technique minimizes variance commonly seen in other manufacturing processes.

One key tip is to invest time in mold design. Flaws in mold design can lead to defects in the final product. Another tip is to maintain equipment regularly. Machinery in poor condition can affect production quality and precision. Always consider the materials used too; different plastics behave uniquely during the injection process.

Manufacturers must pay attention to each detail during production. Even slight changes in temperature or pressure can cause issues. Regularly reviewing production outputs ensures that quality standards are met. There’s always room for improvement in this field, and adapting quickly to feedback is vital.