What is a PU Foam Lamination Machine and How Does It Work?

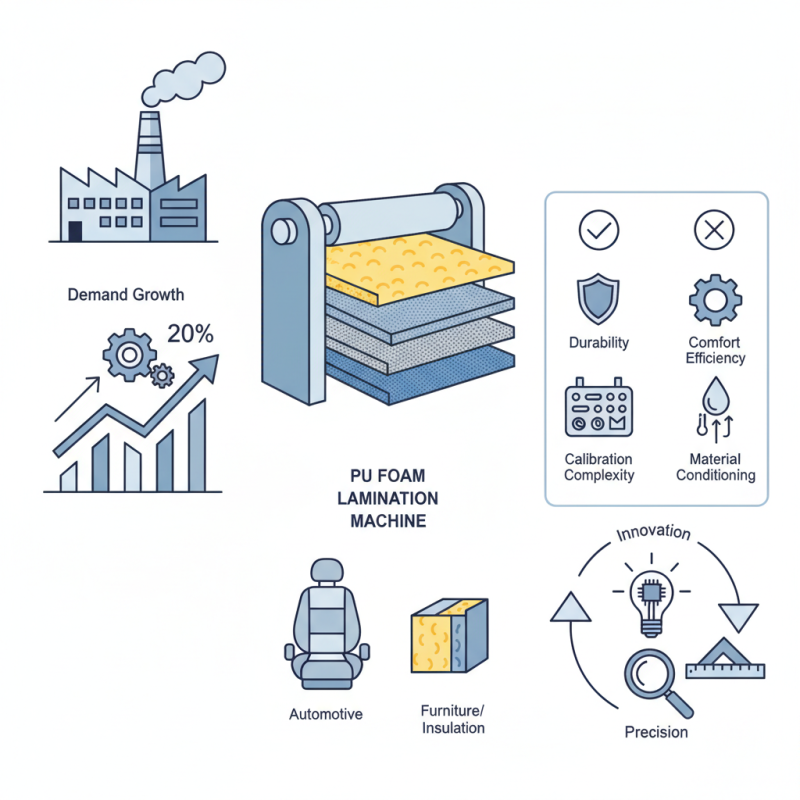

The PU foam lamination machine is an essential tool in industries like furniture and automotive manufacturing. According to market analysis, the demand for PU foam products has surged by 20% over the past five years. This growth has led to increased production needs, making machines such as the PU foam lamination machine integral to efficiency.

These machines bond various materials with PU foam, enhancing durability and comfort. They play a crucial role in various applications, from upholstery to insulation. However, investing in such machinery requires careful consideration. The technology is evolving rapidly, and manufacturers must stay updated to ensure quality and reduce waste.

While the benefits are clear, challenges do exist. The calibration of these machines can be complex, causing waste if not managed properly. Industry reports indicate that ensuring optimal conditioning of materials can be overlooked. Overall, the PU foam lamination machine represents both innovation and a call for precision in manufacturing processes.

What is a PU Foam Lamination Machine?

A PU foam lamination machine is essential in various industries. It bonds polyurethane foam with different materials. These materials often include fabrics, plastics, or other foams. This process enhances durability and surface quality. Reports indicate that the global market for foam lamination is booming. The industry is expected to grow at a CAGR of 5.2% through 2025. This growth highlights the importance of such machines in manufacturing.

The working principle of a PU foam lamination machine involves several steps. First, materials are aligned on a conveyor. The machine then applies adhesive to bond the layers. It utilizes heat and pressure to cure the adhesive. Precision control is crucial here. Even minor deviations can result in poor adherence. Some machines also offer multiple station setups. This allows for simultaneous lamination, improving efficiency.

However, challenges persist in this field. Maintaining consistent quality can be problematic. Variations in temperature or pressure may lead to defects. Operator training is vital. Skilled personnel are needed to address potential issues. Monitoring production closely is essential for achieving desired outcomes. The investment in advanced technology can help mitigate these risks.

What is a PU Foam Lamination Machine and How Does It Work?

| Feature | Description | Applications |

|---|---|---|

| Type of Adhesive | Polyurethane based adhesive | Used in the automotive, furniture, and textile industries |

| Function | Laminates PU foam to various substrates | Mattresses, cushions, soundproofing materials |

| Process | Involves coating, pressing, and curing | Production of multi-layered materials |

| Key Components | Rollers, heating elements, glue applicators | Manufacturing operations |

| Efficiency | High-speed operation improves production | Scaling production capabilities |

| Safety Features | Emergency stop buttons, safety covers | Ensures operator safety during use |

Key Components of PU Foam Lamination Machines

PU foam lamination machines are essential in the manufacturing sector. They streamline the process of applying foam layers to various surfaces efficiently. Understanding the key components of these machines can help industries improve their production.

The main components include the foam application system, the lamination unit, and the cutting mechanism. The foam application system uses advanced spray technology. This ensures even coverage and minimizes wastage. Research shows that efficient application can reduce material costs by up to 30%. The lamination unit applies pressure to bond the foam to the substrate. This often involves rollers or heated plates, which enhance adhesion quality.

Another critical component is the cutting mechanism. It allows for precise trimming of foamed products, which is vital for quality control. Data from industry reports indicate that precision cutting can improve product consistency by nearly 25%. However, maintaining these components can be challenging. Regular maintenance is required to ensure optimal performance. Neglecting this can lead to increased downtime and unexpected costs. Understanding these components is crucial for anyone involved in manufacturing. It's often the small, overlooked details that can significantly impact production efficiency and output quality.

PU Foam Lamination Machine Production Efficiency

The Lamination Process Explained Step-by-Step

The lamination process uses adhesive to bond different materials together. It involves several steps, each critical to achieving the desired result. Typically, a PU foam lamination machine starts with feeding the base material through rollers. This step requires precise control of speed and pressure.

Next, a layer of polyurethane foam is applied. This foam is known for its flexibility and durability. The thickness of the foam can significantly affect the final product. Industry studies show that laminated materials can enhance tear resistance by up to 30%. After application, the materials pass through a heating section. This ensures proper adhesion and allows the foam to cure.

**Tips:** Regular maintenance of the machine is essential for consistent results. Check the temperature settings often to avoid overheating. A clean surface on all materials prevents imperfections during lamination.

Once the lamination is complete, the finished product can be trimmed and inspected. Quality control is crucial here. Sometimes, the adhesion may not go as planned. Reassessing the material properties or bond strength helps address this. Understanding these factors leads to improvements in future productions.

Applications of PU Foam Lamination in Various Industries

PU foam lamination is a versatile process utilized across various industries. Furniture manufacturers benefit from this technique to create comfortable and durable products. The lamination adds a layer of protection, enhancing resistance to wear and tear. Additionally, it improves aesthetics, making furniture more appealing to consumers.

In the automotive industry, PU foam lamination plays a crucial role as well. It is used in seat cushioning and interior components. The laminated foam absorbs impact and provides comfort during long rides. However, challenges exist. Some manufacturers struggle with the consistency of adhesion. This inconsistency can lead to product defects, making quality control essential.

Textile industries also utilize PU foam lamination widely. It is common in producing mattresses and bedding materials. The foam layer adds support and enhances sleep quality. Yet, there are considerations. Environmental impacts of foam production and disposal raise concerns. Finding sustainable alternatives is vital. As manufacturers adopt this technology, addressing these issues becomes increasingly important.

Benefits of Using PU Foam Lamination Machines

PU foam lamination machines are crucial in creating versatile products. They combine layers of materials with polyurethane foam, enhancing both function and comfort. These machines are popular across various industries. The benefits they offer can significantly impact product quality and production efficiency.

Using a PU foam lamination machine can result in several advantages. First, it improves thermal insulation in products. This is especially beneficial in furniture and automotive sectors. Additionally, the lamination process can enhance durability. Products become more resistant to wear and tear, ensuring a longer lifespan. It’s also worth noting that the adhesive used in lamination creates a strong bond between layers, contributing to product stability.

Another key benefit is the customization potential. Manufacturers can easily adjust thickness and density. This flexibility allows for tailored solutions based on specific needs. However, it's essential to consider the initial setup costs. Investing in high-quality machines may lead to better long-term savings. But sometimes, companies hesitate to commit fully. Balancing cost with quality remains a challenge for many. Each choice encompasses a range of uncertainties that require careful thought.